"Powering Efficiency with Advanced Motor Technologies"

The quality of the steel laminations in an asynchronous induction motor is

The quality of the steel laminations in an asynchronous induction motor is

mainly determined by the material, manufacturing process, and machining precision.

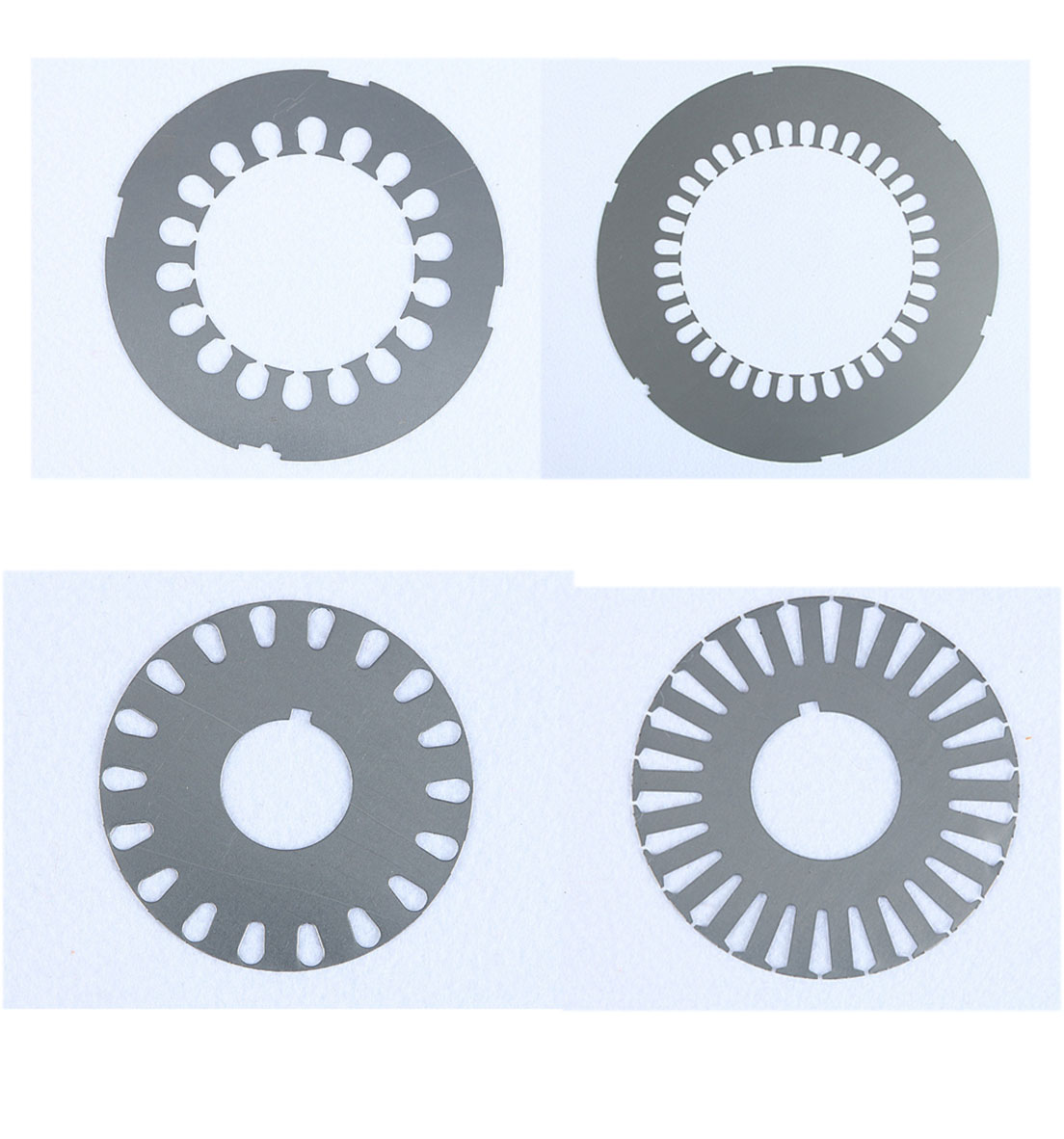

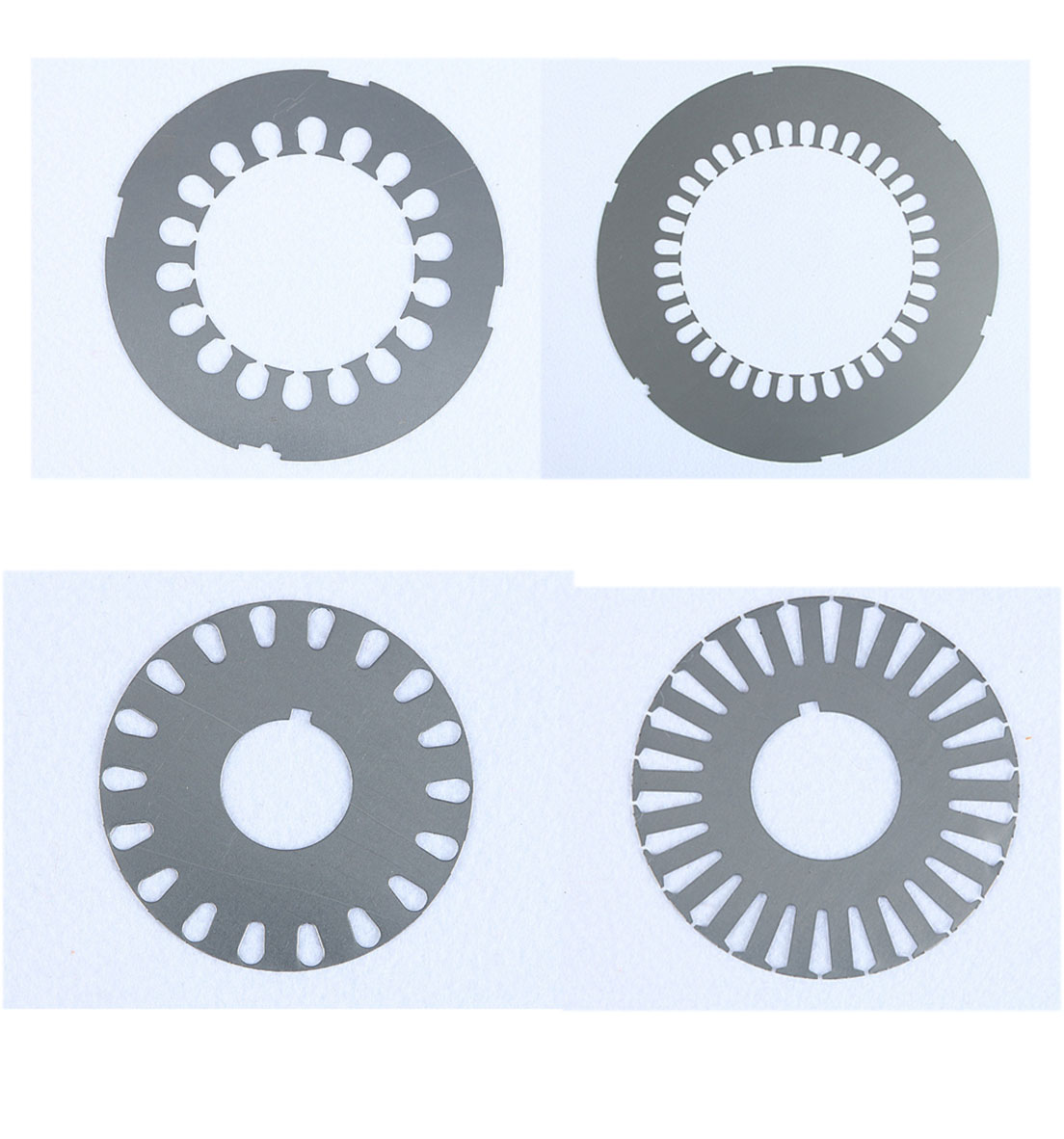

Steel laminations are a critical component in both the stator and rotor of the motor,

significantly affecting motor performance, especially efficiency and heat generation.

Here are some key criteria to evaluate the quality of induction motor steel laminations:

Material Quality:

Silicon Steel: The most common material for motor laminations is silicon steel (cold-rolled electrical steel).

The silicon content in the steel directly impacts the motor's magnetic performance. Steel laminations

with higher silicon content typically offer lower core losses and better magnetic permeability.

Low Loss: Core loss is an important factor in evaluating the performance of the steel.

Steel laminations with low core loss reduce energy waste and improve motor efficiency.

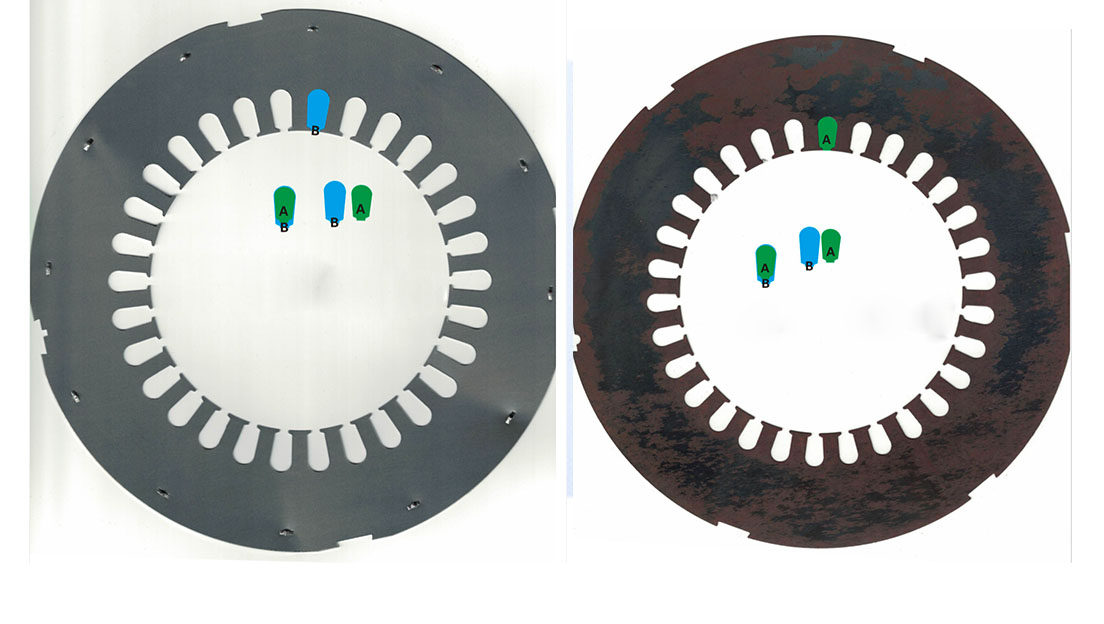

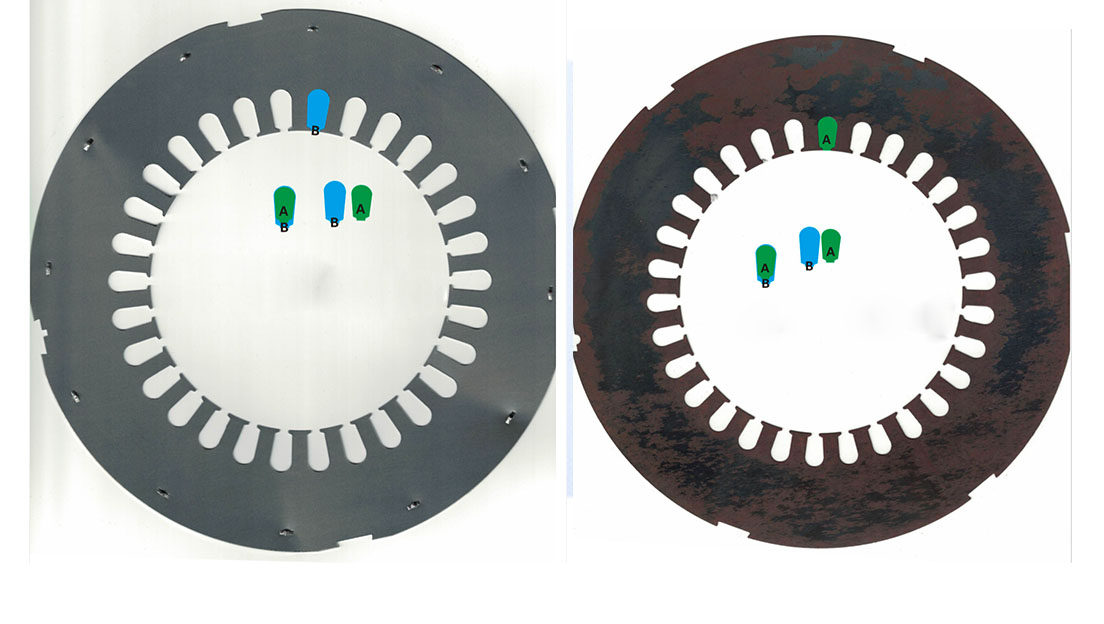

Surface Coating:

Steel laminations are often coated with a thin insulating layer to reduce eddy current losses,

prevent short circuits between laminations, and improve corrosion resistance.

Steel with uniform and intact coatings typically indicates higher quality.

Thickness and Precision:

The thinner the steel laminations, the lower the eddy current losses.

High-quality laminations are usually thinner and manufactured with high dimensional accuracy,

ensuring proper alignment when stacked together.

Grain Orientation:

Steel laminations are often manufactured with a specific grain orientation to optimize magnetic properties.

The correct grain orientation leads to better magnetic flux distribution and lower core losses.

Electrical Conductivity:

Steel laminations should have low electrical conductivity to minimize eddy current losses,

which contribute to heating and reduced motor efficiency.

In summary, high-quality steel laminations should be made from high-silicon steel with low core losses,

a protective coating, precise thickness, and proper grain orientation to ensure optimal motor performance and efficiency.