“High vs Low-Quality Electric Motors: Understanding the Impact on Performance and Efficiency”

When analyzing articles about the quality of electric motors for a company website,

there are a few key elements to consider in order to ensure the content is informative,

credible, and aligned with the brand's goals. Here’s a breakdown of factors to cover:

1. Introduction to Electric Motors

Start with a brief overview of electric motors, their importance, and how they work.

1. Introduction to Electric Motors

Start with a brief overview of electric motors, their importance, and how they work.

This sets the context for the reader, especially for those who may not be familiar with the technical details.

2. Factors Affecting Motor Quality

Efficiency: High-quality motors are energy-efficient, which means they consume

less power for the same output. This can lower operating costs and reduce environmental impact.

Durability: A good electric motor should have a long lifespan, be resistant to wear and tear, and function effectively in different environments.

Reliability: Reliability is key. A motor that fails frequently can lead to costly downtime and maintenance.

Performance: High-performance motors deliver the expected output with minimal energy loss and operational noise.

Materials: The quality of materials used (such as the stator, rotor, bearings, etc.) can greatly influence the motor's overall quality and performance.

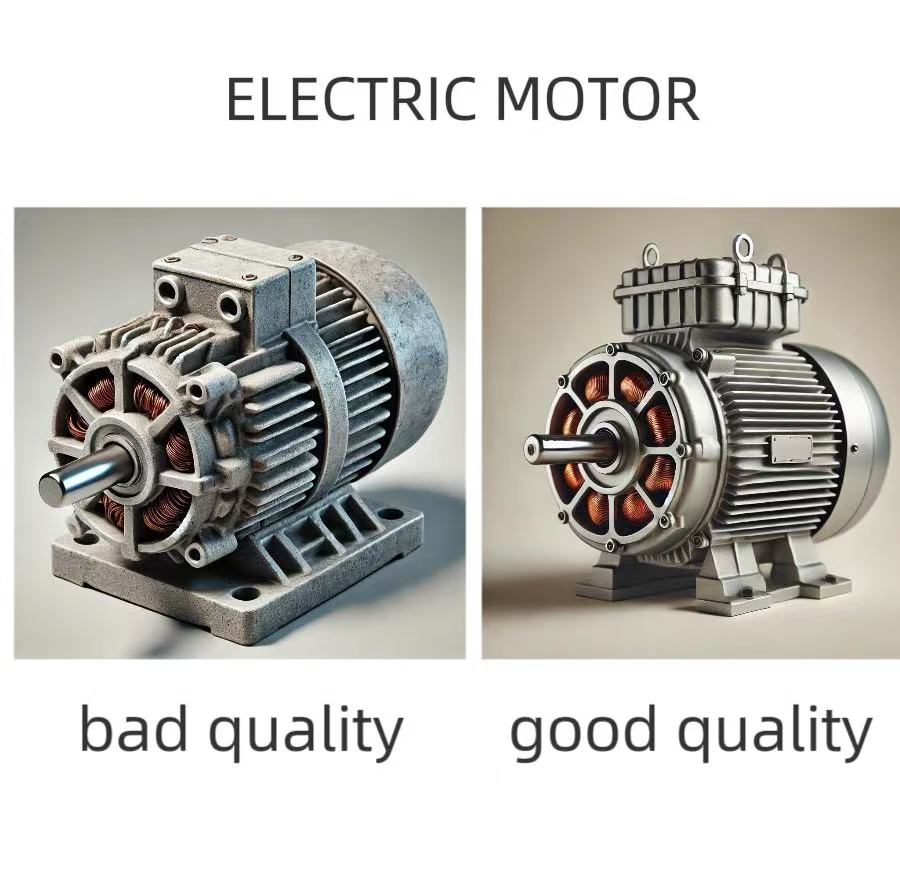

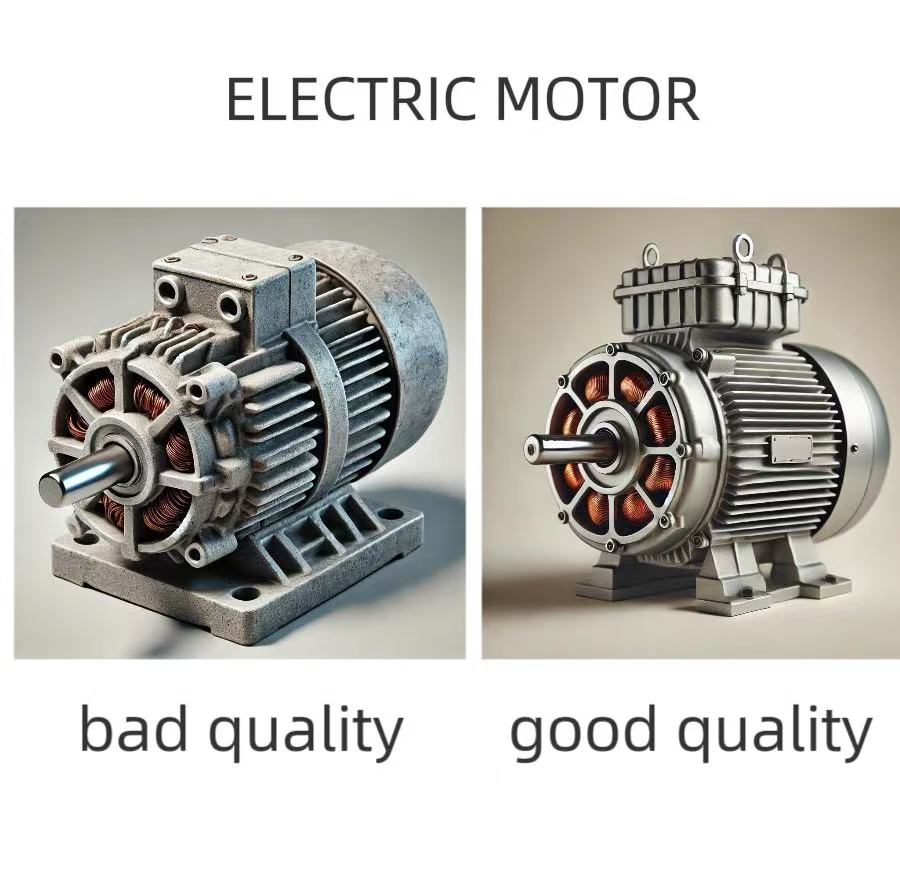

3. Common Problems in Poor-Quality Electric Motors

Overheating: Low-quality motors tend to overheat because they are less efficient, causing damage to internal components.

Vibration: Poor balancing or low-grade bearings can result in vibrations, leading to motor instability and reduced lifespan.

Inconsistent Power Output: Motors that fail to maintain stable power output are inefficient and unreliable.

Wear and Tear: Motors built with subpar materials will show signs of wear much sooner, requiring frequent repairs and replacement.

4. How to Choose the Right Electric Motor**

- **Application-Specific Needs**: Select motors designed for their intended use (e.g., industrial, automotive, household).

- **Energy Efficiency Ratings**: Look for motors with high efficiency ratings (e.g., IE3, IE4 standards).

- **Manufacturer Reputation**: Choose motors from reputable manufacturers with a proven track record.

- **Certifications and Standards**: Ensure compliance with industry standards (e.g., ISO, CE, UL).

- **Warranty and Support**: A strong warranty and accessible customer support reflect the manufacturer’s confidence in their product.

5. Maintenance Tips for Electric Motors**

- **Regular Inspections**: Schedule routine checks to identify issues like overheating or unusual noises early.

- **Proper Lubrication**: Ensure bearings and moving parts are well-lubricated to reduce friction and wear.

- **Clean Environment**: Keep the motor and its surroundings free of dust and debris.

- **Temperature Monitoring**: Use sensors to monitor operating temperatures and prevent overheating.

- **Professional Servicing**: Engage qualified technicians for periodic maintenance and repairs.

6. Conclusion**

Investing in high-quality electric motors is essential for achieving operational efficiency, cost