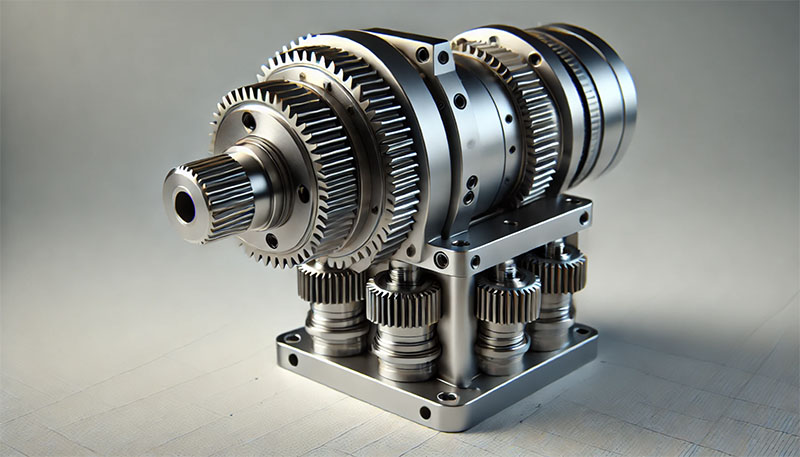

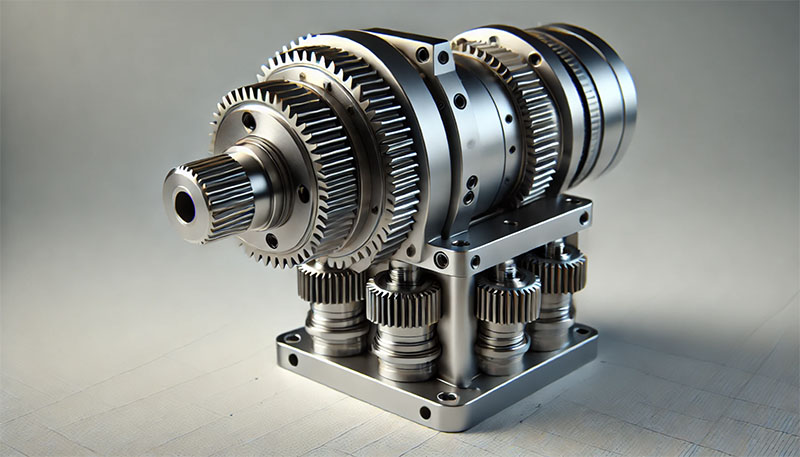

Precision Gearbox Reducer for CNC Machines

Precision gearbox reducers are critical components in CNC machines, providing enhanced control and precision in motion systems. These devices are designed to reduce the speed of an electric motor while increasing the torque output, ensuring smooth and efficient operation in high-precision environments like CNC machining. A well-designed gearbox reducer not only optimizes the performance of CNC machines but also contributes to the longevity and reliability of the system.

In CNC machines, precision is paramount. The movement of cutting tools must be finely controlled to produce accurate parts, and any deviation can lead to costly errors. Precision gearbox reducers address this by offering highly accurate torque control and maintaining stable positioning of the motor. This results in improved product quality, especially when working with complex or delicate materials.

Gearbox reducers are available in various configurations, including planetary, helical, and worm gear types, each suited to different applications in CNC machinery. Planetary gearbox reducers, for instance, are favored for their high torque density and compact design, making them ideal for use in space-constrained setups without sacrificing performance.

Efficiency is another key benefit of precision gearbox reducers. CNC machines often operate for long periods, and reducing the energy consumption of motors without compromising on output is essential. Precision reducers enable smooth operation at lower speeds, reducing wear and tear on the motor and extending the life of both the motor and the machine.

Yilong is an excellent manufacturer and wholesaler of gearbox reducers. We welcome you to choose Yilong’s gearbox reducers for your precision CNC machine needs.